Gabions Products

- Military Gabions

- Hot Dipped Galvanized Gabion Mesh Cells

- Welded Mesh Gabions Architectural Wall Cladding

- Gabions (Gabiony)

- Galfan + PVC Coated Gabions

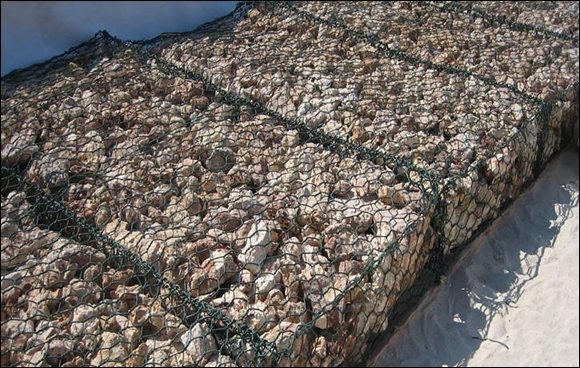

- Gabion Mattresses for Flood Protection Embankment

- Planted Gabion Walls

- Gabions and Geotextiles for Bridge Construction

- Gabion Basket Hot Dip Galvanized

- Gabions P. V. C. Coated Galvanised Wire Box

- Gabions River Training Works

- Geotextile Fabric

- Woven Wire Mesh Cages for Gabion Project

- Gabion Fence

- Welded Gabions Coating Galfan

- Gabion Baskets Double Twisted Galvanized

- Triple Twisted Wire Mesh Gabions

- Gabion Box

- Woven Gabions

- Gabion Baskets

- Wire Mesh Gabion Mattress

- Gabion Cages (Stone Box)

- Gabion Wall

- Hexagonal Gabions Netting

- Gabions Machine

- Welded Gabions

- Sack Gabions

- Reinforced Gabions

- Gabion faced reinforced soil walls

- Gabion Mattress

- Gabions for Water Conservancy

- Gabions for Bridge Protection System

- Gabion Wall Drop Structures

- Modular Gabions as Architectural Elements

- Gravity Wall of Gabions

- Gabions for Headwalls or Wingwalls

- Channel Linings

- Modular Gabions for Rockfall Netting System

Home » About Gabions » Fabrication

Fabrication of Gabions

Gabions shall be fabricated in such a manner that the sides, ends, lid and diaphragms can be assembled at the construction site into rectangular baskets of the sizes specified and shown in the drawings. Gabions shall be of single unit construction: the base, lid, ends and sides shall be either woven into a single unit or edge of these members connected to the base section of the gabion in such a manner that strength and flexibility at the connecting point does not compromise the engineered structural design of the gabion. Where the length of the gabion exceeds one and one half its horizontal width, the gabion shall be divided by diaphragms of the same mesh and gauge as the body of the gabion, into cells whose length does not exceed the horizontal width. The gabion shall be furnished with the necessary diaphragms secured in proper position on the base in such a manner that no additional tying is required at this juncture.

Fabrication

The gabions shall be unfolded on the ground and stretched to the maximum extent possible while ensuring that all creases are in the correct positions for forming the box. Any cutting required shall be carried out so that the cut ends of wire are a minimum of 50 millimetres from the twisted joins. After stretching and cutting as required the side and end panels shall be lifted so that the tops of all sides are level. Any loose ends of wire protruding above a level plane at the top or from the corners shall be bent down into the box. Corners shall be fastened securely and the box shaped prior to commencing any binding.

The binding wire shall be securely fastened to the top of a corner by lacing between two meshes at the corner and twisting the binding wire through three half turns. The wire shall then be laced around the two vertical selvedges, when applicable, and through each mesh in turn in a continuous lacing action and shall be pulled tight before securing to the bottom corner by the three half turns to an adjacent wire.

The diaphragm panels shall then be placed in position and secured to the gabion sides in the same manner as the corners. The empty box shall then be firmly seated on a prepared area in its final position and laced to the adjoining corners or sides of gabions previously placed along all adjoining corners and tops. If additional binding of the gabions is required this shall be shown on the Drawings or specified.

Filling

When boxes used are one (1) metre high or more they shall be cross tensioned in each compartment at third points in the height by wires of the same diameter as the binding wire securely tied by two turns around the mesh or selvedge wire and three half turns around itself. The boxes shall be filled to between 25 and 50 millimetres above their tops. The lids shall be stretched tight over the filling with a crow-bar or similar and wired down in a continuous lacing process in the same manner as that specified for corners. Each edge may be laced with a separate length of binding.

Measurement

The Billed Rate for Gabions shall include for all work specified including excavation, filling, compaction and trimming necessary to construct the gabions to the lines and levels specified. Measurement of the quantity in cubic metres for which payment will be made shall be based on the nominal external dimensions of the gabion baskets which have been constructed in accordance with the Contract. The unit of measurement for Reno mattresses shall be the cubic metre (m3).

Mesh Formation:

The double twisted hexagonal wire mesh shall have deformability sufficient to permit minimum of mesh elongation equivalent to 10% of the unstretched length of the mesh test section without reducing the gauge or the tensile strength of the individual wire strands to values less than those for similar wire, one gauge smaller in diameter.

Non-raveling:

The wire mesh is to be fabricated in such a manner as to be non raveling. This is defined as the ability to resist pulling apart at any of the twists or connections forming the mesh when a single wire strand in a section of mesh is cut.