Gabions Products

- Military Gabions

- Hot Dipped Galvanized Gabion Mesh Cells

- Welded Mesh Gabions Architectural Wall Cladding

- Gabions (Gabiony)

- Galfan + PVC Coated Gabions

- Gabion Mattresses for Flood Protection Embankment

- Planted Gabion Walls

- Gabions and Geotextiles for Bridge Construction

- Gabions P. V. C. Coated Galvanised Wire Box

- Gabions River Training Works

- Geotextile Fabric

- Woven Wire Mesh Cages for Gabion Project

- Gabion Fence

- Welded Gabions Coating Galfan

- Gabion Baskets Double Twisted Galvanized

- Gabion Box

- Woven Gabions

- Gabion Baskets

- Wire Mesh Gabion Mattress

- Gabion Cages (Stone Box)

- Gabion Wall

- Hexagonal Gabions Netting

- Gabions Machine

- Welded Gabions

- Sack Gabions

- Reinforced Gabions

- Gabion faced reinforced soil walls

- Gabion Mattress

- Gabions for Water Conservancy

- Gabions for Bridge Protection System

- Gabion Wall Drop Structures

- Modular Gabions as Architectural Elements

- Gravity Wall of Gabions

- Gabions for Headwalls or Wingwalls

- Channel Linings

- Modular Gabions for Rockfall Netting System

Gabion Mesh Mattresses

Gabion mattresses are rectangular containers made of hexagonal woven steel wire mesh laced together and filled with stones or crushed rock.

Gabion mattress mesh:

The triple-twisted hexagonal mesh material is made up with annealed mild steel wire heavily zinc coated of the following wire sizes:

Type of Wire |

Min. Diameter |

Selvage (perimeter) wire |

3.60 mm |

Mesh wire |

2.82 mm |

Tying and connecting wire |

2.23 mm |

Wires for gabions and mattresses may be polyester coated. The wires shall be resistant to chemical attack in the pH range 2 to 9, be resistant to attack by bacteria, and not be attractive to vermin. They shall also be stable over a temperature range of -60℃ to 100℃ and be resistant to degradation by ultraviolet radiation such that strength loss due to 10 years exposure to sunlight shall not exceed 20%.

Gabion mattresses are used for river bank and scour protection

The mesh shall be securely tied to salvage wires to form rectangular panels which shall be securely wired together to form the completed gabion baskets. The ties and connections for each gabion basket shall comprise not less than 8% of its total weight, and the fabrication shall be all to the satisfaction of the Engineer.

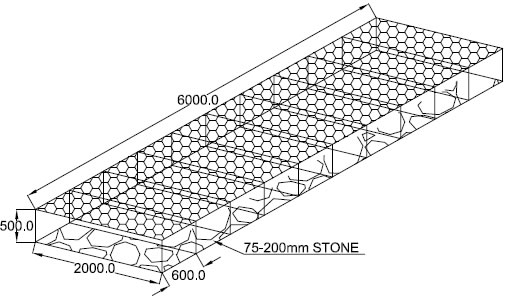

Gabions shall be made to the sizes as shown on the drawings. Gabion mattresses shall be made to sizes shown in WAJ Typical details of trenches for sewer pipes and as per MPWH specifications. Each gabion mattress or compartment of a gabion mattress shall be provided with at least 4 cross- connecting wires.

Gabion Mattress is a double twisted hexagonal woven galvanized steel wire mesh compartmented basket with a rectangular mattress shape. The compartment or cells of the mattress are of equal size and dimension and are formed by internal diaphragms being placed within the basket providing even distribution of the stone fill throughout the mattress even after structural movement. Even distribution of the stone fill ensures that the reno mattress maintains intimate contact with the foundation soil.

Gabion Mattresses have been used for channel linings, river training, soil retention, slope stabilization, and other applications successfully throughout the world for over 100 years. Gabion Mattresses offer many advantages over other types of construction materials.

Advantages offered by double twisted mesh gabion mattresses:

are flexibility, durability, strength, permeability, ecology, reliability, longevity, low cost, and an aesthetic appearance.

Flexibility - the most important advantage of using gabion mattresses

Gabion mattress has a flexibility both for the individual unit and the overall gabion structure. The Double Twisted Hexagonal Mesh construction of the units permits it to tolerate differential settlement without failure. This property is especially important when a structure is on unstable soil conditions or in areas where scour from wave action or currents can undermine the toe of the structure and cause structural settlement.

Durability - achieved by high strength material and structural integrity

Material: Gabion Mattresses are built from high strength double twisted hexagonal mesh and connected together to create a monolithic mass structure capable of undergoing structural movement without any loss of structural integrity creating a highly durable structure.

Strength - to withstand forces generated by water and earth masses - Strength value in ASTM A975-97

The strength of gabion mattresses is achieved in several aspects:

breaking strength;

the mesh wire tensile strength;

Pull apart resistance strength of the mesh;

Corrosion resistance of the mesh.

Permeability - Free Draining Structure

The porous structure permits an active air circulation through the wire netting and soil is deposited and plant growth invades the structure, transpiration further assist in removing moisture from the soil being protected.

Mattress geometry and material properties

Length |

Width |

Height |

6 metre |

2 metre |

0.3 metre |

Galvanised and PVC coated Gabion Mattress

The gabion mattress manufacturer must be ISO 9001 certified and the published technical data and values must be verified by Third Party Quality Assurance according to DIN 18200.

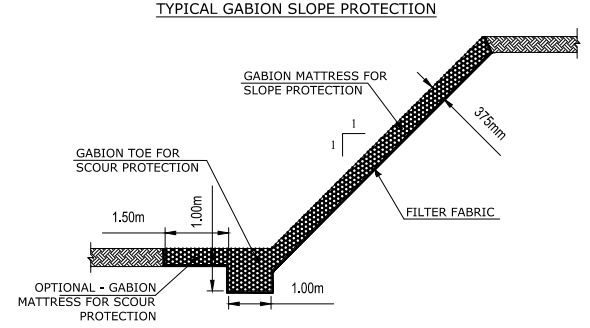

Gabion Mattress 375mm thick for sloper scour protection including filter fabric or concrete slope protection inclusive of necessary design where directed by Engineer.

Gabion Mattresses for Flood Protection Embankment

Triple Twisted Hexagonal Mesh Gabion Mattresses are mostly used in projects of Flood Embankment and intake works. Gabions types are boxes and mattresses. Aerct supplies quality gabions system for flood protection, with detailed requirements for the gabion wire, mesh fabric, filter fabric, stones and construction of gabions work as following.

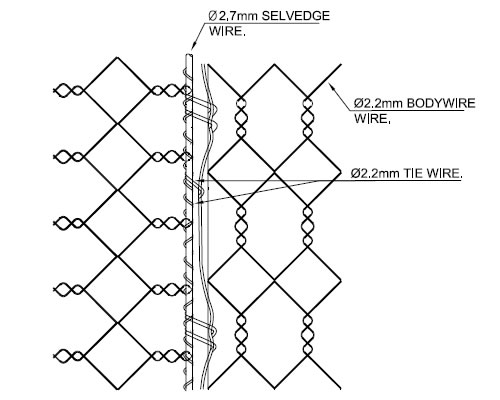

The correct joining of separate gabion mattresses with triple twist every two meshes

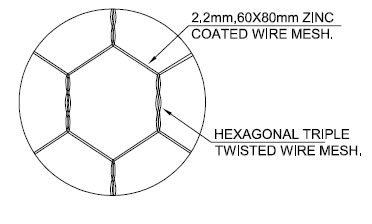

Hexagonal Triple Twisted Wire Mesh Details

Gabion Mattresses to be filled with stones of 75 to 200mm

Technical Requirements of Gabion Mattresses:

1. Wire Fabric for Gabions

All wire used in the fabrication of gabions (including selvage wire and lacing wire) and in the wiring operating during construction (including tie wire) shall be annealed mild steel wire, having an average strength of 38-50 kg/mm2. Wire thicknesses are as given below.

| Gabion type | Wire Size (mm) |

Mesh Size (mm) |

| Box gabions | 2.7 | 80*100 |

| Mattresses | 2.2 | 60*80 |

| Lacing Wire | 2.2 | 150 |

| Selvedge wire(boxes) | 3.4 | |

| Selvedge wire(mattress) | 2.7 | 200 |

All wire shall be galvanized meeting international standard of "Galvanized Coatings on Wire".

The minimum weight of the zinc coating shall be according to the figures shown in the table below:

| Nominal Diameter of wire (mm) |

Minimum weight of coating (gr/mm2) |

| 2.2 | 240 |

| 2.7 | 260 |

| 3.4 | 275 |

The adhesion of the zinc coating to the wire should be such that, when the wire is wrapped six turns round a mandrel of 4 times the diameter of the wire, it does not flake or crack to such an extent that any flakes of zinc can be removed by rubbing with the bare fingers.

Wire mesh fabric shall be hexagonal triple twist mesh. The tightness of the twisted joints shall be such that a force of not less than 1.7kN is required to pull on one wire to separate it from the other wire provided that each wire is prevented from turning and the whole process is done in one plane. Ultimate failure load in the direction of the weave will be about 43 kN/metre length. Longitudinal elongation of mesh will not exceed 10%.

Joining of Gabion Boxes and Mattresses and edge treatment:

The mesh cages shall be subdivided into cells by wire-mesh diaphragms with a maximum

dimension of 1.0 m for boxes, and 2 x 0.6 m for mattresses.

All edges of gabions, diaphragms and end panels shall be selvedged in such a way as to prevent raveling of the mesh and to develop the full strength of the mesh. The amount of lacing wire should be approximately 5% of the gabion weight.

The gabion mesh shall be cut, folded and wired together to form joints, angles, curves or slopes which are not possible to obtain in the structures with the standard rectangular gabions, the mesh must be cleanly cut, and the surplus mesh cut completely out, or folded back or on to, and neatly wired to an adjacent gabion face. The cut edges of the mesh shall be securely laced together with binding wire.

2. Filter Fabric for Gabion Mattresses Embankment Works

Gabions and mattresses should be laid on a filter fabric.

The filter fabric shall be of a non-woven melted fabric consisting of a mixture of polypropylene and polythene or other similar materials. The fabric shall be resistant to ultra violet rays and sunlight.

Where overlapping of fabric is required, the overlap shall not be less than 500 mm and shall be sewn with a lock type stitch in such a manner that it produce a joint as durable as the fabric.

The grade of fabric shall weigh not less than 350 gr/m2 and have a thickness of 0.5 mm.

Tensile strength shall be not less than 2kN/m. Permeability (ViH50) shall be not less than 60l/s*m2.

Storage and handling of the fabric in no case shall be the geotextile be exposed to direct sunlight, ultra violet rays, temperature greater than 60o C, mud, dirt, dust and debris, to the extent that its strength, toughness or permeability characteristics are diminished.

In some cases it will be necessary to cut back the fine sand layer in the bank to a depth of 20 cm and replace with as-dug river gravel.

3. Stones for Gabions

Stone used for gabions and gabion mattresses shall be clean, natural, hard and durable with a minimum density of 2,650 kg/m3. Stone shall be well graded within the following limits, but at least 85% by weight of the rock fragments shall have a size equal to or larger than 100 mm. No rock shall be capable of passing through the mesh.

| Gabion type | Minimum dimension (mm) |

Maximum dimension (mm) |

| Box gabions | 100 | 250 |

| 170 mm mattress | 75 | 120 |

| 230 mm mattress | 75 | 150 |

| 300 mm mattress | 75 | 200 |

| 500 mm mattress | 75 | 200 |

Stone shall preferably be rounded rather than angular.

4. Method of Construction

a. Gabions and gabion mattresses shall have internal diaphragms of the same mesh as the enclosing fabric.

b. Gabion shall be installed in a workmanlike manner, the gabion shall be placed on smooth surface, final line and grade shall be approved by engineer.

c. Rock pieces shall be generally uniformly graded from 75mm to 200mm for mattresses, 100mm to 200mm for gabion box.